When equipment has been shut down, then de-energized using an energy-isolating device, nothing will prevent the energy-isolating device from accidently (or intentionally) being turned on, reopened, or …

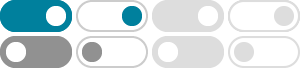

This is generally done by affixing the appropriate lockout or tagout devices to energy-isolating devices and by de-energizing machines and equipment. The standard outlines the steps required to do this.

owever, some people have a misunderstanding of exactly what is - or is not - an energy isolation device. According to the definition section in the OSHA lockout/tagout standard, an energy iso. atio. device is …

The purpose of Safe Work Practice 506: Breaking Lines, Isolating, and Release of Equipment are to specify the minimum steps that must be followed to reduce the risk of fire, spill, or injury when …

Prepare a specific lockout/tagout checklist for each piece of equipment. Although it is not required by the standard, we recommend that these checklists be printed, laminated and attached to the machines …

‘Isolation’ is the separation of that plant or equipment from every source of energy (pressure, electrical, fuel, heat, mechanical, etc) in such a way that the separation is secure.

This guide is based on the requirements in Oregon OSHA’s standard for hazardous energy control – Subdivision 2/J, 1910.147, which protects employees who could be injured as a result of the …